Trusted company that deals in quality-made products

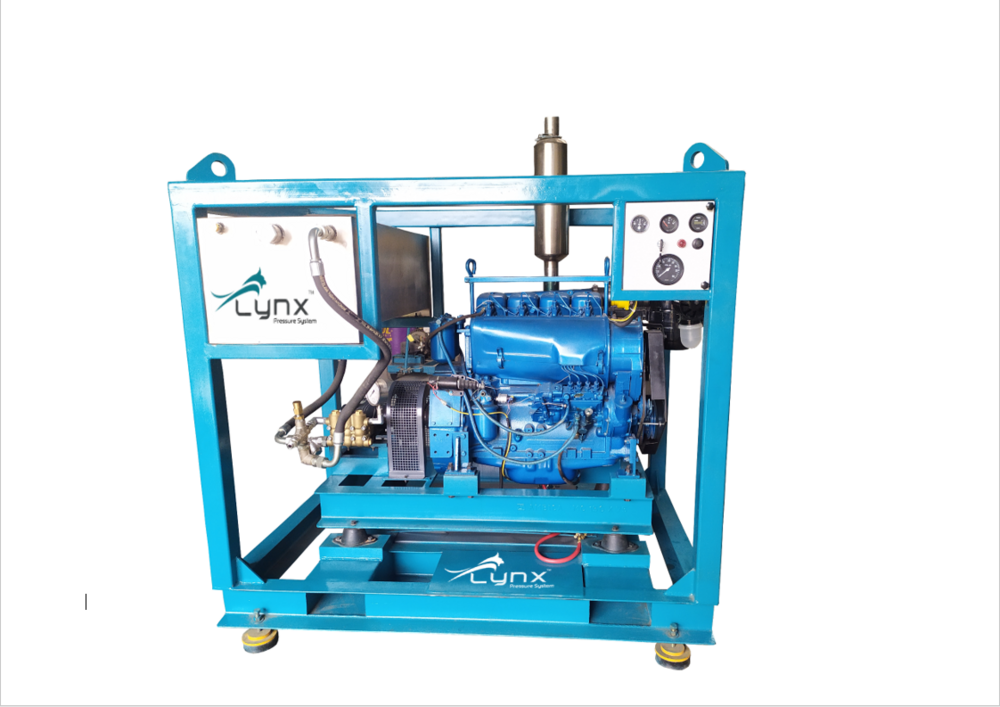

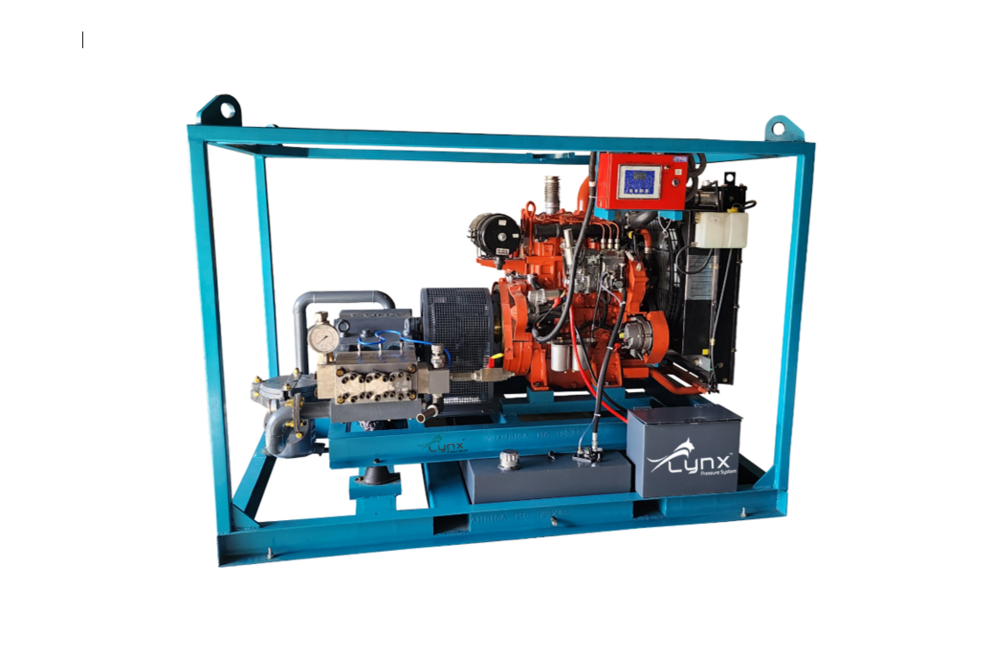

Water Jet Blasting Machines

285000 INR/Set

Product Details:

- Usage Industrial

- Size Standard

- Product Type Triplex High Pressure Plunger Pumps System

- Color Blue

- Power 30 Horsepower (HP)

- Voltage 220-440 Volt (v)

- Click to View more

X

Water Jet Blasting Machines Price And Quantity

- 285000 INR/Set

- 1 Set

Water Jet Blasting Machines Product Specifications

- 220-440 Volt (v)

- Standard

- Blue

- Industrial

- 30 Horsepower (HP)

- Triplex High Pressure Plunger Pumps System

Water Jet Blasting Machines Trade Information

- Ahmedabad

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Western Union, Paypal, Cheque

- 75 Set Per Month

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- Wooden box with bubble plastic wrapping, Export packaging, As per client demand.

- Australia, Eastern Europe, Western Europe, Middle East, South America, Central America, North America, Asia, Africa

- Dadra and Nagar Haveli, Meghalaya, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, West India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Karnataka, Kerala, Maharashtra, Mizoram, Manipur, Nagaland, Odisha, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Lakshadweep, South India, Madhya Pradesh, North India, East India, Andhra Pradesh, Central India, Jharkhand, Chhattisgarh, Himachal Pradesh, All India

- MSME, IEC

Product Description

Water Jet Blasting Machinecan effectively remove a wide variety of tough dirt in difficult-to-reach points or locations in a safe and efficient manner. In fact, the results are comparable to those of cleaning techniques that use abrasives and cleaning agents, but without the dust and other health hazards, which allows the workers to focus on their daily tasks in a health-friendly workplace environment.We Lynx Pressure System are manufacturer ofWater Jet Blasting Machinesin Ahmedabad; Gujarat; India. We also export Hydro Blasting Machine to many countries such as UAE, South Africa and many more....HAWK Pump PXI model selection chart: MODEL FLOW PRESSURE POWER LPM GPM PSI BAR HP KW PXI 15 4 7250 500 20 15 5440 375 15 11.18 4715 325 12.5 9.32 PXI 21 6 7250 500 30 22.37 5800 400 25 19 4785 330 20 15 Water Blasting Cleaning Applications: High Pressure Cleaning Tank & Vessel Cleaning Hydro Blasting Hydro demolition Paint Removal Ship Hull Cleaning Heat Exchanger-Condenser-Boiler-Evaporator Tube & Surface Cleaning Surface Preparation Textile Industrial Work for Humidification Clean and test pressure of petrol pipeline, chemical container, reaction kettle, and heat exchanger by salt work Pharmaceutical factory and concrete removal and roughening Remove sand, oil, rust, colloid, paint and dirty stuff of castings Remove bread crust in rotary kiln of cement plant.

FAQs of Water Jet Blasting Machines:

Q: What is the power capacity of the Water Jet Blasting Machine?

A: The Water Jet Blasting Machine has a power capacity of 30 Horsepower (HP).Q: What size is this machine available in?

A: The machine is available in a standard size.Q: What voltage range is required for operating the machine?

A: The machine operates within a voltage range of 220-440 Volt (v).Q: What is the color of the Water Jet Blasting Machine?

A: The machine is blue in color.Q: What is the primary usage of the machine?

A: The Water Jet Blasting Machine is designed for industrial usage.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free