Trusted company that deals in quality-made products

हीट एक्सचेंजर ट्यूब क्लीनिंग मशीन

650000.00 आईएनआर/Set

उत्पाद विवरण:

- पावर सोर्स

- उपयोग Industrial

- मटेरियल

- टाइप करें

- शर्त

- फ्यूल टाइप

- उपयोग करें ,

- अधिक देखने के लिए क्लिक करें

X

हीट एक्सचेंजर ट्यूब क्लीनिंग मशीन मूल्य और मात्रा

- सेट/सेट्स

- सेट/सेट्स

- 1

हीट एक्सचेंजर ट्यूब क्लीनिंग मशीन उत्पाद की विशेषताएं

- वोल्ट (v)

- Heat Exchanger Tube Cleaning Machine

- Industrial

- Blue

हीट एक्सचेंजर ट्यूब क्लीनिंग मशीन व्यापार सूचना

- पूरे भारत में

- 15 प्रति महीने

- 7 हफ़्ता

- Yes

- हमारी नमूना नीति के बारे में जानकारी के लिए हमसे संपर्क करें

- क्लाइंट की मांग के अनुसार, प्लास्टिक रैपिंग, एक्सपोर्ट पैकेजिंग के साथ लकड़ी का बॉक्स।

- , , , , , , , ,

- ऑल इंडिया, , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , ,

- MSME, IEC

उत्पाद वर्णन

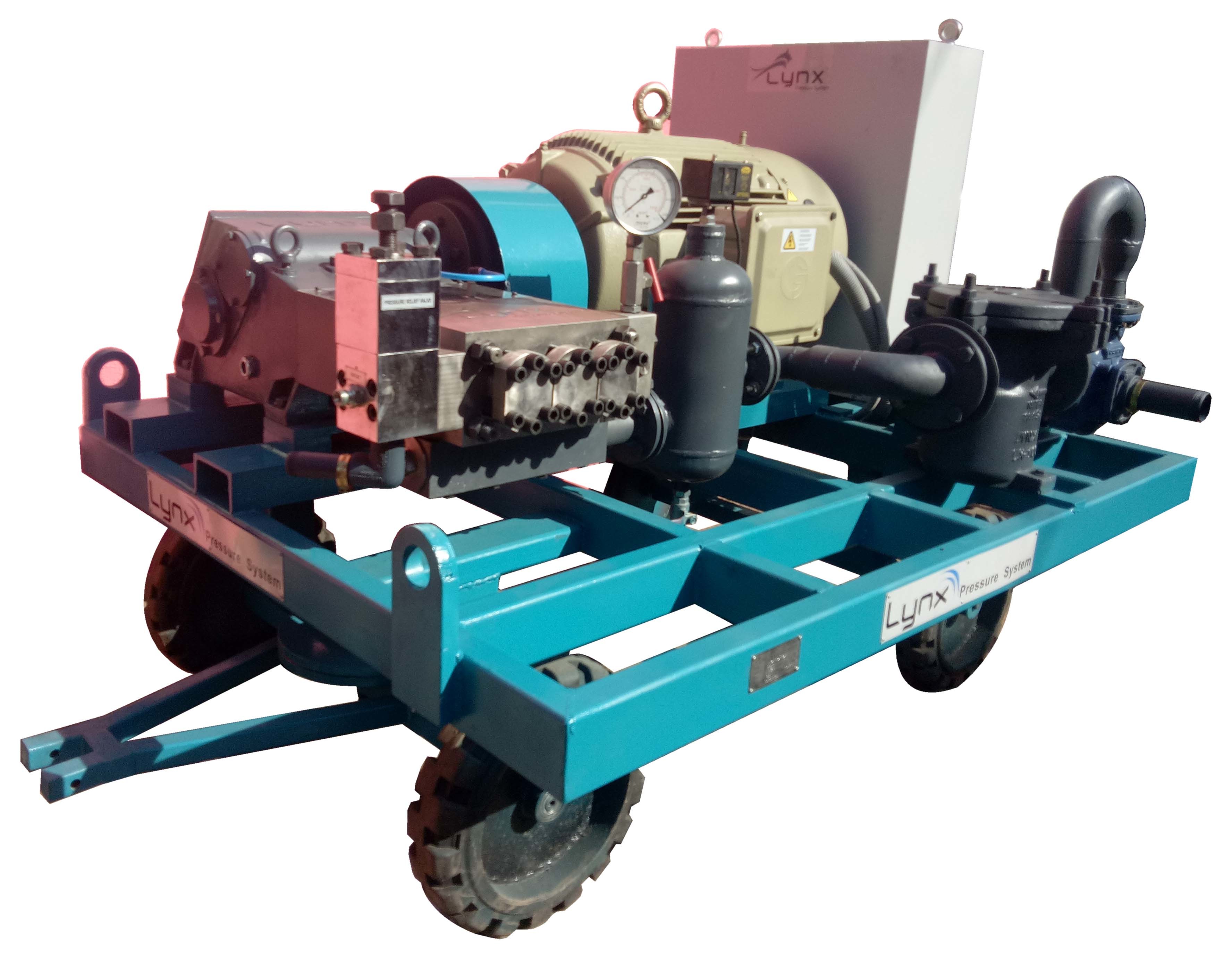

Hydro Jetting Machine Pressure for Heat Exchanger Tube Cleaning Pump MachineProblem: Industries whereHeat exchangersare used regularly face problem of material deposition in and on tube bundles. This deposition reduces efficiency of Heat exchanger. It is very difficult to remove deposition manually, this process is less effective and it is also risky.Solution: Lynx Pressure SystemmakesWater/Hydro Jetting Machinewith complete systems helps to clean the inside tube and outside. Our System helps to clean 2 or more tubes at a time with effectiveness and also reduce time to clean by 70%.High Pressure Pumps Accessories: High Pressure Dump Gun, Conventional Tube Cleaning Nozzles, SS Rigid Lance, Flexible Lance, Pressure Regulating Valve, Safety Valve, etc. Hydro Jetting Machine Model Selection: MODEL FLOW RATE (LPM) MAX. RATED PRESSURE - kg/cm2(Motor - hp) PXI 17.350 17 350 (15) - - PXI 21.500 21 500 (30) - - MPX 30.500 30 500 (40) - - BMP18 30 500 (40) - - MP3575P 35 620 (60) 750 (75) 1000 (100) MP4580P 45 500 (60) 625 (75) 840 (100) MP5270P 52 - 530 (75) 720 (100) MF24 62 655 (100) 790 (120) - MF26 73 560 (100) 670 (120) 770 (150) HP42140P 42 900 (100) 1000 (120) 1400 (150) HP52110P 52 - 880 (120) 1100 (150) HP60100P 60 - - 1000 (180)FAQs of Heat Exchanger Tube Cleaning Machine:

Q: What is the power source of the Heat Exchanger Tube Cleaning Machine?

A: The Heat Exchanger Tube Cleaning Machine is powered by electricity.Q: What type of cleaning process does this machine use?

A: It uses a cold water cleaning process.Q: What material is the machine made of?

A: The machine is made of metal.Q: What is the voltage requirement for the Heat Exchanger Tube Cleaning Machine?

A: The machine operates at 440 Volt (v).Q: Is this machine suitable for industrial usage?

A: Yes, the machine is designed for industrial usage.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese