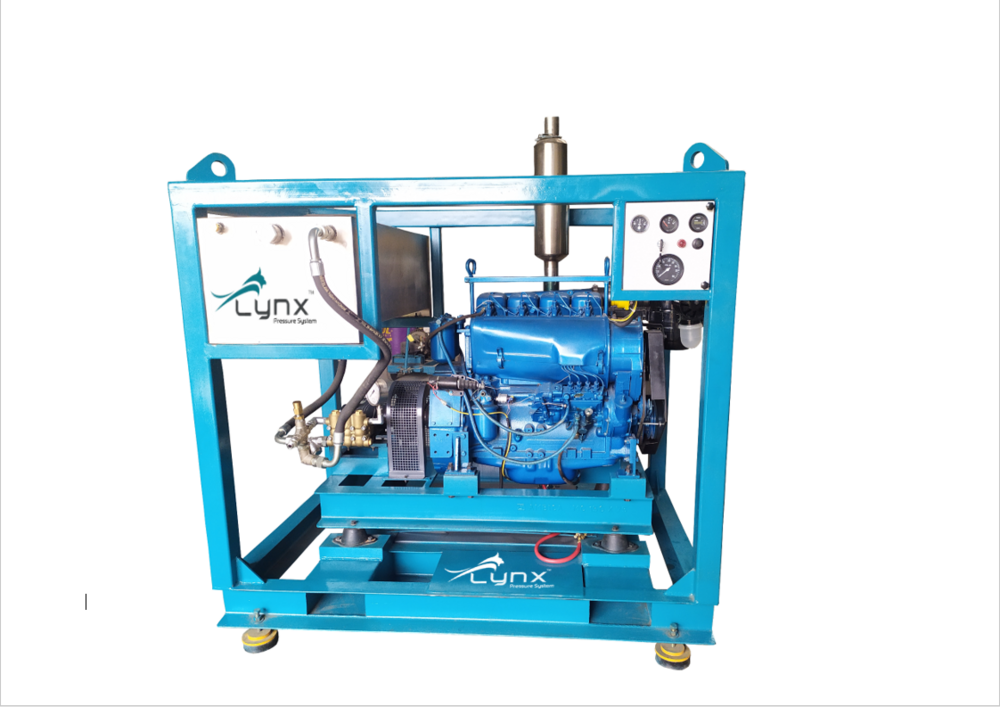

Pressure Test Pump 150 BAR

Product Details:

- Max Suction 2-3 Bar

- Inlet/Outlet 3/4

- Theory Reciprocating Pump

- Flow Rate 50 LPM

- Material Brass Head

- Structure Piston Pump

- Power Electric

- Click to View more

Pressure Test Pump 150 BAR Price And Quantity

- 100000.00 INR/Set

- 1 Set

Pressure Test Pump 150 BAR Product Specifications

- 3/4

- Maritime

- High Pressure

- Other

- Pressure Test Pump 150 BAR

- Reciprocating Pump

- Blue

- 50 LPM

- Electric

- Brass Head

- 2-3 Bar

- Water

- Piston Pump

Pressure Test Pump 150 BAR Trade Information

- Ahmedabad

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque, Telegraphic Transfer (T/T), Western Union

- 150 Set Per Month

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- Wooden boxes with bubble plastic wrapping, Export packaging, As per client requirement

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Dadra and Nagar Haveli, Himachal Pradesh, South India, Central India, North India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chhattisgarh, Chandigarh, Delhi, Daman and Diu, Gujarat, Goa, Jammu and Kashmir, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Nagaland, Odisha, Pondicherry, Rajasthan, Telangana, Tripura, Uttar Pradesh, West Bengal, Manipur, Sikkim, Andaman and Nicobar Islands, Uttarakhand, Lakshadweep, Haryana, Tamil Nadu, Punjab, Jharkhand, All India

- MSME, IE

Product Description

We are a client centric firms, affianced in manufacturing, exporting and supplying premium grade Electric Hydro Pressure Test Pump 150 BAR. This pump is manufactured by our skilled professionals with the use of fine quality components. The provided pump is used for measuring pressure in gas cylinders, vessels and boilers in varied industries. Apart from this, the offered product can be availed at cost effective rates.

Features:

-

Trouble free working

-

Require less maintenance

-

User friendly operations

-

Sturdiness

Electric Hydro Pressure Test Pump 150 BAR Specification:

| Type | Triplex Style Plunger Pumps |

| Model No | XLT 50.150 |

| Flow Rate | 50 LPM |

| Min. Pressure | 75 BAR |

| Max. Pressure | 150 BAR |

| Motor (HP) | 10HP - 20HP |

Durable Brass Head for Reliable Operation

This pressure test pump is fitted with a solid brass head, which ensures excellent resistance to corrosion and mechanical wear. This feature is particularly valuable for continuous use in harsh maritime and industrial environments. Brass construction not only enhances longevity but also contributes to stable, high-pressure performance.

High-Pressure Performance for Rigorous Testing

With a maximum pressure capacity of 150 BAR and flow rate of 50 LPM, this pump meets the demands of rigorous water and hydraulic pressure testing. Its piston pump structure, powered by electricity, offers rapid and reliable pressure build-up, making it ideal for industrial processes requiring efficiency and precision.

Versatile Applications in Water and Maritime Industries

Engineered for adaptability, the 150 BAR pressure test pump seamlessly manages various water and industrial testing needs. Its sturdy construction, efficient power delivery, and standard 3/4 inch connections make it suitable for a wide array of operational scenarios, particularly within maritime sectors.

FAQs of Pressure Test Pump 150 BAR:

Q: How is the Pressure Test Pump 150 BAR used in industrial and maritime applications?

A: This pump is designed for water pressure testing in various industrial and maritime settings. It reliably tests pipes, vessels, and installations by delivering high-pressure water through a reciprocating piston mechanism, ensuring pipeline and equipment integrity.Q: What materials and components ensure the pumps durability?

A: The pump features a robust brass head, which resists corrosion and enhances strength, making it suitable for challenging environments. Its electric-powered piston pump structure ensures consistent performance and long operational life.Q: When should I use the 150 BAR Pressure Test Pump?

A: Use this pump whenever precise and reliable high-pressure water testing is required, especially during the commissioning, maintenance, or inspection of water pipes, boilers, pressure vessels, and maritime equipment.Q: Where can the Pressure Test Pump 150 BAR be installed?

A: This pump is versatile and can be set up anywhere with suitable electrical supply and water sources. It is particularly effective aboard ships, at dockyards, in industrial plants, or wherever high-pressure testing is necessary.Q: What is the process for operating this test pump?

A: To operate, connect water supply to the 3/4 inch inlet, ensure proper electrical connection, and start the pump. Adjust set points as needed the brass head withstands high pressure while the piston action efficiently builds up the required force for your testing needs.Q: What are the key benefits of using this specific test pump?

A: Its high-pressure capability, durable brass construction, and efficient electric motor provide optimal reliability. The pumps design ensures consistent flow, corrosion resistance, and suitability across several water and maritime applications, simplifying routine as well as intensive testing operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free