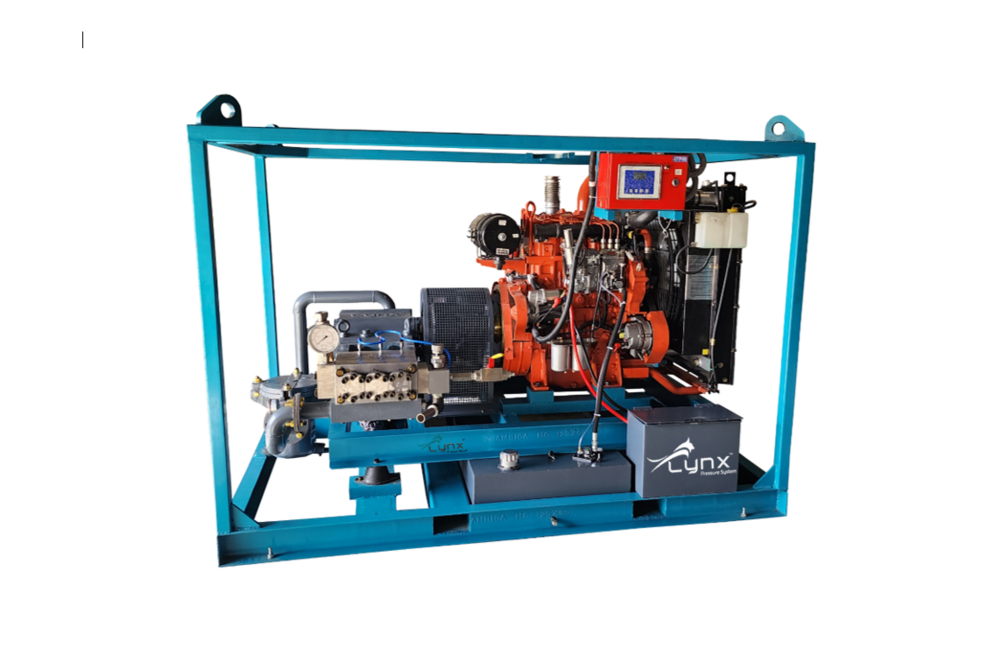

Diesel operated Hydro Blasting Machines

Product Details:

- Usage Industrial

- Size Standard

- Product Type Diesel operated Hydro Blasting Machines

- Application Stone, Mining, Chemical Industry

- Color Blue

- Voltage 220 Volt (v)

- Click to View more

Diesel operated Hydro Blasting Machines Price And Quantity

- 1 Set

- 195000.00 INR/Set

Diesel operated Hydro Blasting Machines Product Specifications

- Diesel operated Hydro Blasting Machines

- Blue

- Stone, Mining, Chemical Industry

- Industrial

- 220 Volt (v)

- Standard

Diesel operated Hydro Blasting Machines Trade Information

- All over India, Mumbai, Mundra, Pipavav, Kandla

- 25 Set Per Month

- 3 Week

- Yes

- Contact us for information regarding our sample policy

- Wooden boxes with bubble plastic wrapping, Export packaging, As per client demand.

- Asia, Australia, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, North America

- Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Manipur, Andaman and Nicobar Islands, Pondicherry, Uttarakhand, Daman and Diu, Lakshadweep, South India, North India, East India, West India, Assam, Arunachal Pradesh, Bihar, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Punjab, Rajasthan, Sikkim, Telangana, Tripura, Uttar Pradesh, West Bengal, Nagaland, Kerala, Tamil Nadu, Andhra Pradesh, Central India, Odisha, Chhattisgarh, All India

- MSME, IE

Product Description

Hydro-blasting, commonly known as water blasting, is commonly used because it usually requires only one operator. In hydro blasting machine, a highly pressured stream of water is used to remove old paint, chemicals, or buildup without damaging the original surface. This method is ideal for cleaning internal and external surfaces because the operator is generally able to send the stream of water into places that are difficult to reach using other methods. Another benefit of hydro-blasting is the ability to recapture and reuse the water, reducing waste and mitigating environmental impact.

We Lynx Pressure System are manufacturers of Electric & Diesel operated Hydro Blasting Machines in Ahmedabad; Gujarat; India.

We also export Hydro Blasting Machine to many countries such as UAE, South Africa and many more..

Hydro Blasting Machine Model Selection:

| MODEL | FLOW RATE (LPM) | MAX. RATED PRESSURE - kg/cm2 (Motor - hp) | ||

| PXI 17.350 | 17 | 350 (15) | - | - |

| PXI 21.500 | 21 | 500 (30) | - | - |

| MPX 30.500 | 30 | 500 (40) | - | - |

| BMP18 | 30 | 500 (40) | - | - |

| MP3575P | 35 | 620 (60) | 750 (75) | 1000 (100) |

| MP4580P | 45 | 500 (60) | 625 (75) | 840 (100) |

| MP5270P | 52 | - | 530 (75) | 720 (100) |

| MF24 | 62 | 655 (100) | 790 (120) | - |

| MF26 | 73 | 560 (100) | 670 (120) | 770 (150) |

| HP42140P | 42 | 900 (100) | 1000 (120) | 1400 (150) |

| HP52110P | 52 | - | 880 (120) | 1100 (150) |

| HP60100P | 60 | - | - | 1000 (180) |

Features:

- Robust Construction

- Few Moving Parts

- Low and Easy Maintenance

- Simple and Comfortable Design

- Easy Installation

- Volumetric Efficiency 95% (maximum)

- Independent alloy steel high wear resistance cylinder

- Compulsory lubrication system

- Plunger core automatic regulate device

- Super-hard alloy or ceramic plunger

- All-in-one transmission case

- Equipped with protection unit for phase failure and over charge

- Intake pressure and lubricant pressure warning device

Applications:

- High Pressure Cleaning

- Tank & Vessel Cleaning

- Hydro Blasting

- Hydro demolition

- Paint Removal

- Ship Hull Cleaning

- Heat Exchanger-Condenser-Boiler-Evaporator Tube & Surface Cleaning

- Surface Preparation

- Textile Industrial Work for Humidification

- Clean and test pressure of petrol pipeline, chemical container, reaction kettle, and heat exchanger by salt work

- Pharmaceutical factory and concrete removal and roughening

- Remove sand, oil, rust, colloid, paint and dirty stuff of castings

- Remove bread crust in rotary kiln of cement plant

Powerful Cleaning for Tough Industrial Needs

Our Diesel operated Hydro Blasting Machines excel in tackling stubborn dirt, residues, and materials across diverse sectors, such as stone processing, mining, and chemical industries. The combination of diesel power and 220-volt operation ensures adaptable and consistent performance in demanding environments, making these machines ideal for heavy-duty applications.

Versatile and Durable Construction

The machines feature a standard, industrial-grade design, finished in blue, and are manufactured to withstand tough conditions. Their diesel operation offers flexibility where electrical supply is inconsistent, enhancing their usefulness in remote or high-mobility settings.

FAQs of Diesel operated Hydro Blasting Machines:

Q: How does a diesel operated hydro blasting machine work for industrial cleaning?

A: A diesel operated hydro blasting machine uses a high-pressure stream of water, powered by a diesel engine, to clean surfaces in industries such as stone, mining, and chemicals. The device removes difficult contaminants, scales, or residues by directing powerful jets, providing deep and thorough cleaning without damaging the underlying material.Q: What are the main applications of these hydro blasting machines?

A: These machines are primarily used in stone and mining operations for scale, dust, and residue removal, as well as in the chemical industry for cleaning tanks, reactors, and pipelines. They cater to a wide range of industrial cleaning requirements where conventional methods may fall short.Q: When should I consider using a diesel operated hydro blasting machine over other cleaning methods?

A: You should choose a diesel hydro blasting machine when dealing with extensive, tough, or hazardous residues that require deep cleaning. It is especially suitable when the site has limited electrical infrastructure, or when surface preparation without chemicals is essential.Q: Where are these machines typically installed or used in India?

A: These machines are widely used across industrial sectors in India, including quarries, mining fields, stone processing plants, and chemical factories. Their portability makes them suitable for both stationary and mobile cleaning within these sectors.Q: What is the process for operating the machine safely?

A: Before use, operators should check all connections and ensure safety gear is worn. The machine should be started according to the manufacturers guidelines, with water supply and pressure adjustments monitored consistently. Following maintenance and operational protocols minimizes risks during industrial cleaning tasks.Q: How can users benefit from using these hydro blasting machines?

A: Using these machines ensures efficient, eco-friendly cleaning with reduced downtime and minimal secondary waste. Their high-power output tackles heavy deposits, helping businesses meet safety and productivity standards while reducing reliance on harsh chemicals or manual labor.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free