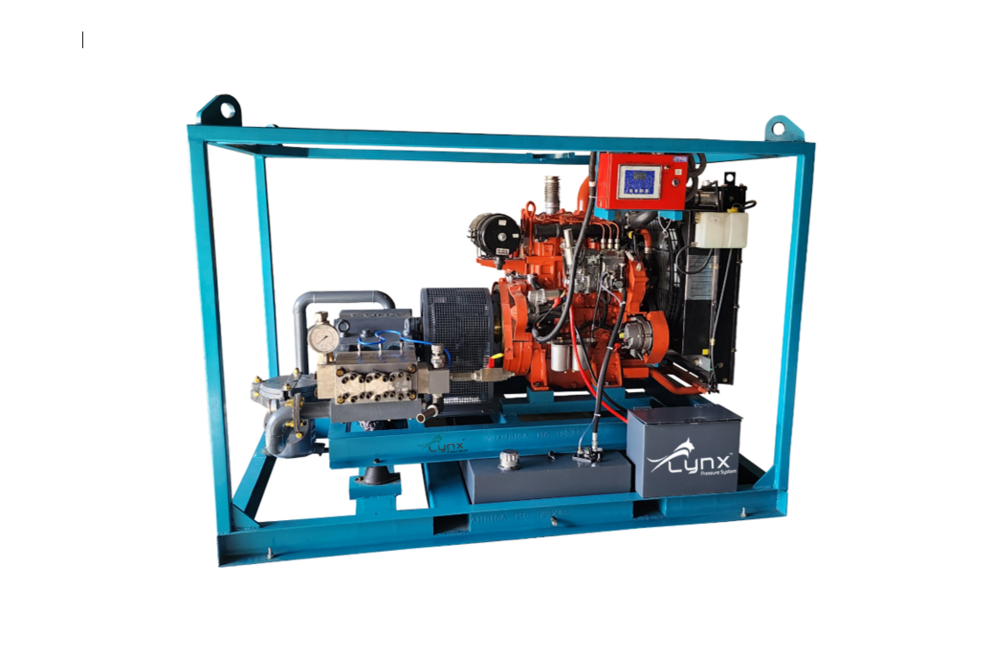

High Pressure Hydro Jet Blasting Machine

Product Details:

- Usage Industrial

- Motor Type Heavy Duty Electric Motor

- Size Standard

- Dimension (L*W*H) 1200 mm x 800 mm x 1000 mm Millimeter (mm)

- Weight Approx. 250 kg Kilograms (kg)

- Product Type High Pressure Hydro Jet Blasting Machine

- Application Pipe, Vessel, Tank Cleaning, Industrial Surface Preparation

- Click to View more

High Pressure Hydro Jet Blasting Machine Price And Quantity

- 1000000.00 INR/Set

- 1 Set

High Pressure Hydro Jet Blasting Machine Product Specifications

- Heavy Duty Electric Motor

- 220-440 Volt (v)

- 22 kW Watt (w)

- Standard

- High Pressure Hydro Jet Blasting Machine

- Robust, Compact

- Blue

- Industrial

- 1200 mm x 800 mm x 1000 mm Millimeter (mm)

- Pipe, Vessel, Tank Cleaning, Industrial Surface Preparation

- Approx. 250 kg Kilograms (kg)

High Pressure Hydro Jet Blasting Machine Trade Information

- All over India, Mumbai, Mundra, Pipavav, Kandla

- Cheque, Telegraphic Transfer (T/T), Western Union

- 15 Set Per Month

- 4 Week

- Yes

- Contact us for information regarding our sample policy

- Wooden boxes with bubble plastic wrapping, Export packaging, As per client demand.

- Dadra and Nagar Haveli, Himachal Pradesh, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, Lakshadweep, South India, West India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Goa, Haryana, Jammu and Kashmir, Jharkhand, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Nagaland, Kerala, All India, Delhi, Gujarat, Karnataka, North India, East India, Andhra Pradesh, Central India, Odisha, Chhattisgarh, Uttar Pradesh

- MSME, IE

Product Description

Water Blasting, commonly known as High Pressure Hydro Jet Blasting Machine, is commonly used because it usually requires only one operator. In hydro blasting, a highly pressured stream of water is used to remove old paint, chemicals, or buildup without damaging the original surface. This method is ideal for cleaning internal and external surfaces because the operator is generally able to send the stream of water into places that are difficult to reach using other methods. Another benefit of hydro-blasting is the ability to recapture and reuse the water, reducing waste and mitigating environmental impact. We Lynx Pressure System are manufacturers of High Pressure Hydro Jet Blasting Machine in Ahmedabad; Gujarat; India. We also export High Pressure Water Jet Blasting Machine to many countries such as UAE, South Africa and many more...

-

Hydro Jetting Machine Model Selection:

MODEL

FLOW RATE (LPM)

MAX. RATED PRESSURE - kg/cm2 (Motor - hp)

PXI 17.350

17

350 (15)

-

-

PXI 21.500

21

500 (30)

-

-

MPX 30.500

30

500 (40)

-

-

BMP18

30

500 (40)

-

-

MP3575P

35

620 (60)

750 (75)

1000 (100)

MP4580P

45

500 (60)

625 (75)

840 (100)

MP5270P

52

-

530 (75)

720 (100)

MF24

62

655 (100)

790 (120)

-

MF26

73

560 (100)

670 (120)

770 (150)

HP42140P

42

900 (100)

1000 (120)

1400 (150)

HP52110P

52

-

880 (120)

1100 (150)

HP60100P

60

-

-

1000 (180)

High Pressure Hydro Jet Blasting Systems Features:

- Robust Construction

- Few Moving Parts

- Low and Easy Maintenance

- Simple and Comfortable Design

- Easy Installation

- Volumetric Efficiency 95% (maximum)

- Independent alloy steel high wear resistance cylinder

- Compulsory lubrication system

- Plunger core automatic regulate device

- Super-hard alloy or ceramic plunger

- All-in-one transmission case

- Equipped with protection unit for phase failure and over charge

- Intake pressure and lubricant pressure warning device

Applications:

- High Pressure Cleaning

- Tank & Vessel Cleaning

- Hydro Blasting

- Hydro demolition

- Paint Removal

- Ship Hull Cleaning

- Heat Exchanger-Condenser-Boiler-Evaporator Tube & Surface Cleaning

- Surface Preparation

- Textile Industrial Work for Humidification

- Clean and test pressure of petrol pipeline, chemical container, reaction kettle, and heat exchanger by salt work

- Pharmaceutical factory and concrete removal and roughening

- Remove sand, oil, rust, colloid, paint and dirty stuff of castings

- Remove bread crust in rotary kiln of cement plant

Efficient Industrial Cleaning Power

Designed for rigorous industrial use, this hydro jet blasting machine combines high pressure with a robust build to tackle heavy-duty cleaning of pipes, tanks, and vessels. Its stainless steel nozzles and heavy steel frame guarantee longevity, while the water-cooled motor allows continuous, safe operation under demanding conditions.

Versatile Control and Enhanced Safety

With both manual and automatic control systems, you can customize operations according to task requirements. Critical safety features such as overload protection and a pressure relief valve help prevent equipment damage and operator hazards during high-pressure blasting processes.

Compact Design with High Mobility

Although made with a strong steel frame, the machines compact design and wheeled base ensure it remains highly mobile. The adjustable hose length (10-40 meters) extends operational reach, making it adaptable for various industrial environments and cleaning applications.

FAQs of High Pressure Hydro Jet Blasting Machine:

Q: How does the High Pressure Hydro Jet Blasting Machine operate for industrial cleaning applications?

A: This machine uses a triplex plunger pump to deliver water at pressures ranging from 500 to 1500 bar, allowing for deep cleaning and surface preparation of industrial equipment such as pipes, tanks, and vessels. The operator can select manual or automatic control modes to optimize the blasting process according to the specific cleaning task.Q: What safety features are included in the machine and how do they protect users?

A: Key safety components include overload protection and a pressure relief valve, which protect both users and the equipment by preventing excessive pressure buildup or operational overloads. Additionally, the water-cooled system helps maintain optimal temperature during extended use.Q: When is it advisable to use manual versus automatic control in operation?

A: Manual control is ideal for tasks requiring precision and hands-on adjustments, such as targeting hard-to-reach areas. Automatic control streamlines standardized or repetitive jobs, improving efficiency during large-scale cleaning or surface preparation projects.Q: Where can this hydro jet blasting machine be effectively used?

A: It is suited for industrial settings that require high-pressure cleaning, such as factories, refineries, shipyards, and manufacturing plants. Typical applications are pipe descaling, vessel decontamination, tank cleaning, and industrial surface preparation.Q: What is the process for setting up the machine before use?

A: Setup involves connecting the appropriate hoses, selecting the nozzle suited for the application, ensuring water supply, and adjusting pressure and control settings. Safety checks, such as verifying the pressure relief valve and overload protection status, are vital before starting operation.Q: How does the machine improve cleaning efficiency compared to traditional methods?

A: The hydro jet blasting machine delivers high-pressure water through stainless steel nozzles, effectively removing tough residues, corrosion, and contaminants faster and without abrasive chemicals. This reduces downtime and enhances overall cleanliness, making it more efficient than manual scrubbing or chemical cleaning.Q: What are the benefits of its robust and compact design for industrial users?

A: A robust construction enhances durability under challenging industrial conditions while the compact design, combined with wheel-mounted mobility, enables easy transport and maneuverability across different job sites, adding flexibility and usability for distributors, exporters, manufacturers, and suppliers in India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free